TEAM THERMOFORMINGS AND ALLIEDS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TEAM THERMOFORMINGS AND ALLIEDS

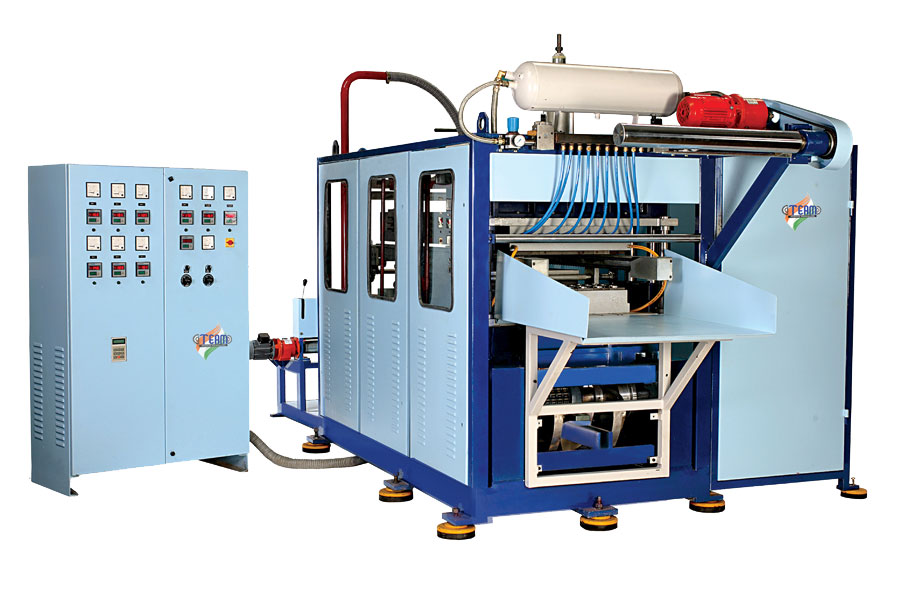

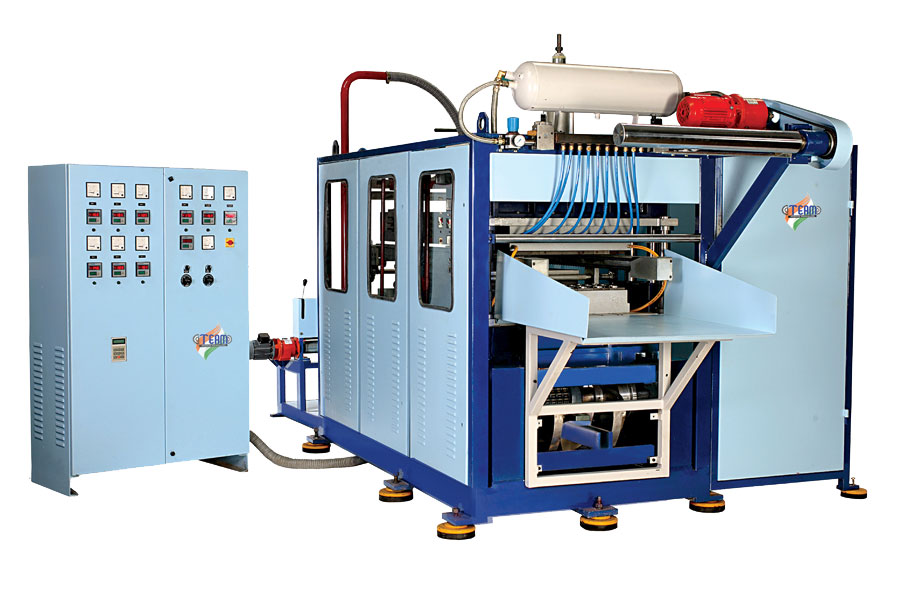

Thermoforming Machines

The Sigma-7(Punch) machine with the integrated hole punching, stacking, counting and unloading station is the ideal machine for high output production of coffee lids and nursery seeding pots. The machine is used for the manufacture of coffee lids and nursery seeding pots made of PS, PP, PET and others. It reduces the production costs with maximum output.

The Robust Design Structure Of Machine Allows For High Speeds And Highly Precise Starting Positions Are Achieved Through The Digital Control Movements

The Bottom Tilting Platform Rotate A Rotation Of 75° Permitting Precise Rapid Ejection, Which Are Then Transported To The Hole Punching Unit.

The Patent Pending Tilting System Uses A Combination Of Servomotor Driven Crank And Levers, Based On An Innovative Electronic Cam System.

This Guarantees Absolute Precision And Repeatability Of The Movement And A Controlled Distribution Of Forces Both During The Platform Movement And In The Cutting Phases Of The Cycle.

The Mould Closing Unit Stands Out By Many Innovative Details And Is Based On A 5-Point Toggle Lever Mechanism Allow Maximum Force Up To 400KN.

The Machine Is Equipped With A Vacuum System Activator On The Bottom Of The Ejectors During The Operation Of Convey Of The Pieces Produced Into The Stacker Channels.

Special Design Features With A Positive Influence On Product Quality Are The Highly Precise Linear Guides Under The Moving Mould Platform.

A Closed Lubrication System Of The Sliding Bearing, Bushes, Sealed Bearing Points Of The Toggle Lever And Guarantees A Mould Compartment Free Of Lubricant.

The Machine Equipped With A Latest Generation, Software Technology That Provides Perfect Management Of All The Cycle Parameters And Machine Functions.

The G3 Operator Interface Panels Give You Complete HMI Functionality For PLCs, Motor Drives And Other Communications-Capable Devices.

Single Cam Thermoformoing Machines

These high speed Thermoforming Machines are mechanically driven by cam and follower system. They are ideal for in-station forming and cutting of containers with flat or semi rolled (bent lip) edges. These machines use moulds with built-in punching dies that guarantee complete concentricity of forming and cutting. This ensures high outputs from moulds with small number of cavities.

Specially Designed, High Precision Linear Guide Ways Parallel To The Moving Mould Pattern Enhance The Product Quality.Ceramic Heaters Are Controlled By PIC Temperature Controls. Lower Heating Bank With PP Controls Is Also Available. Reel Holder With Automatic Unwinding And Wastage Rewind Units Are Standard Features.

Many Innovative Details Have Made The Mould Closing Unit Unique. It Is Based On A Cam Follower Mechanism.The Mechanical Drive Guarantees Repetition Of Forming And Cutting Cycles , With Absolute Accuracy Of Time, Speed And Quality. Indexing Of Plastic Sheet Is Controlled By A Toothed Chain To Minimize Wastage.

Automatic Cup Stacker

The TEAM stacking system offers a flexible and reliable stacking solution designed for high-speed production, complete with low maintenance, an ergonomic working height of one meter at the end of the conveyor belt with large buffer capacity.

Automatic Cup Stacker Mostly Using The Configuration Principle Of The Plastic Cups, Adopt The Combined Convey Device Of Mechanism Driving, Flat Conveyer Belt And Round Conveyer Belt

Scrap Grinders

Description / Specification of Scrap Grinders

We are involved in offering a wide range of Scrap Grinders to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Scrap Grinders. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

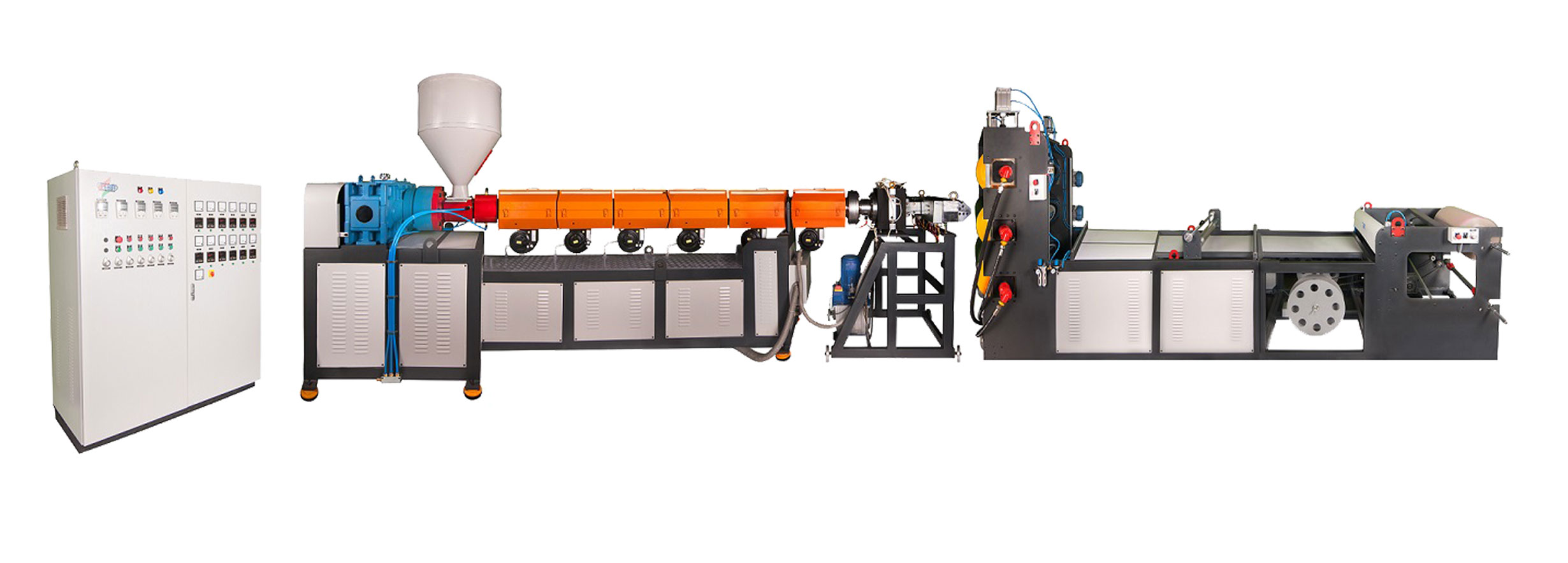

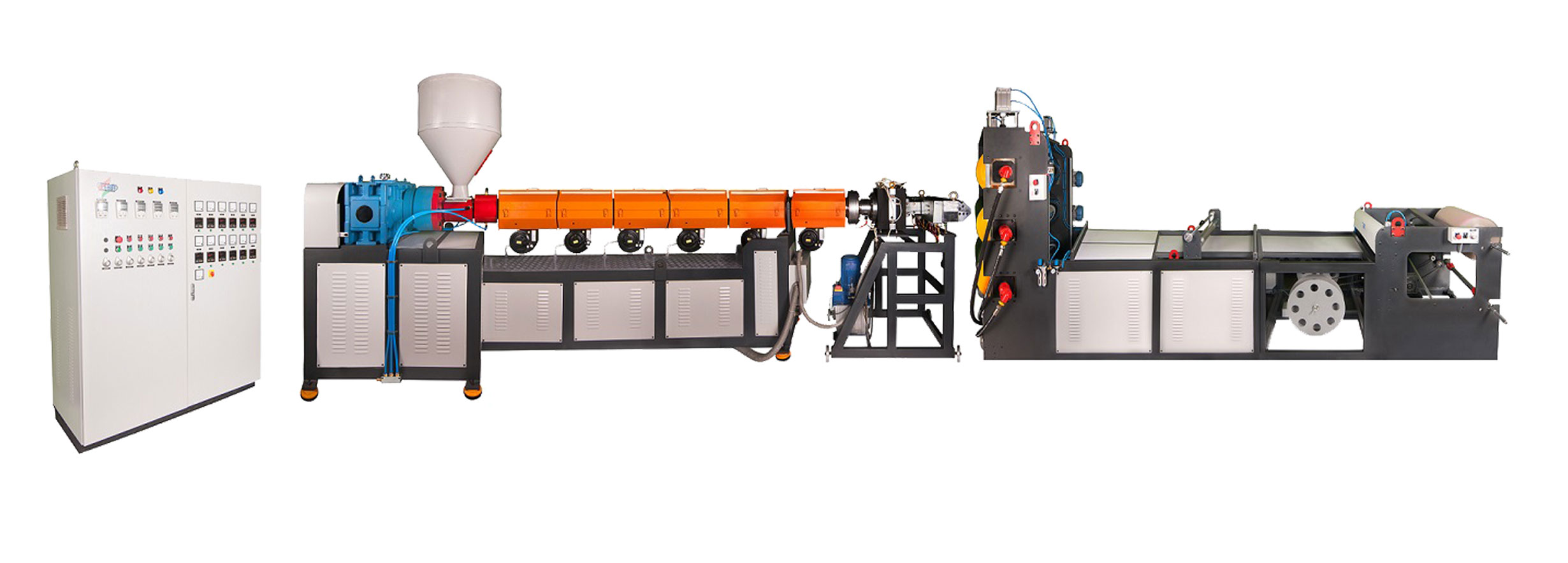

Sheet Extrusion Line

The machine is used for manufacturing plastic sheets of PP, PS, HIPS, etc.

The sheet-line machine is a combination of extruder, calendar, winder and electric control console.

The screw and barrel are made of high quality alloy steel EN- 41 B with optimum hardness and strong corrosion resistance.

The roughness spectrum of rollers range from high mirror gloss surfaces with a roughness value up to Rmax < 0.3 µm.

The Vertical 3-Roll Calendar Unit Is Assembled On A Robust Support Frame. Polish Rolls Are Made Of Hardened Alloy Steel. It Is Provided With A Helicoidally Controlled Internal Cooling Chamber For Circulation Of Thermo-Regulated Cooling Fluid.The Dies Are Designed With Rheological Properties On CAD Systems. These Chrome Plated Dies With Polished Flow Surfaces Are Made Of Corrosion Proof Forged Alloy Steel. They Incorporate Rectangular Section Inlets For Multi-Layer Sheets And Flexible Lip Outlet To Control Thickness Perfectly.

On Offer Are Single And Multi-Layer Co-Extrusion Feed Blocks Up To Three Layers With Provision To Adjust The Melt Flow. Uniquely Designed Screen Changer Reduces Residual Time And Pressure Loss. It Also Keeps The Flow Channel Rheological.Hydraulically Operated Continuous Screen Changers Are Also Offered As Optionals.

The Dies Are Designed With Rheological Properties On CAD Systems. These Chrome Plated Dies With Polished Flow Surfaces Are Made Of Corrosion Proof Forged Alloy Steel. They Incorporate Rectangular Section Inlets For Multi-Layer Sheets And Flexible Lip Outlet To Contact Thickness Perfectly.

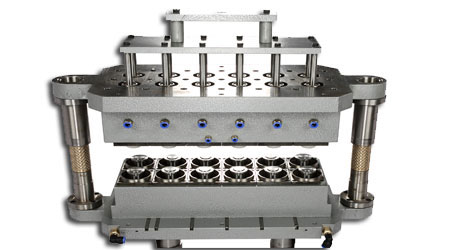

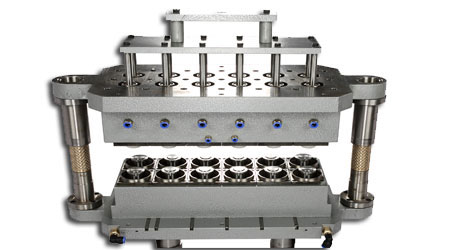

Thermoforming Moulds

At TEAM, the development of moulds and tools is an integrated part of planning and designing, new machines and plants.

Every mould is entirely designed by TEAM, right from product evaluation to tool design till the final test. High quality materials and highly advanced techniques are used to manufacture these dies.

Mould parts are manufactured using a range of up-to-date digital controlled machines which allow the production of standard components and perfectly changeable spare parts.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.